Polished Concrete & Pavilion Finish Concrete

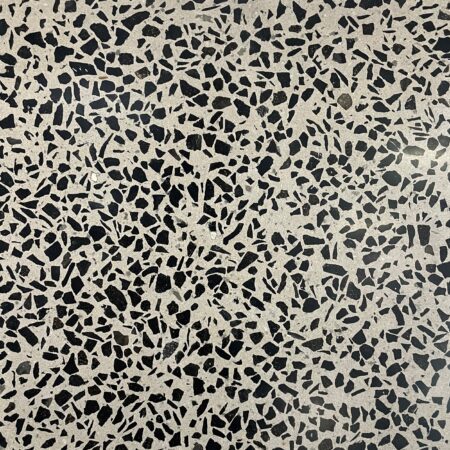

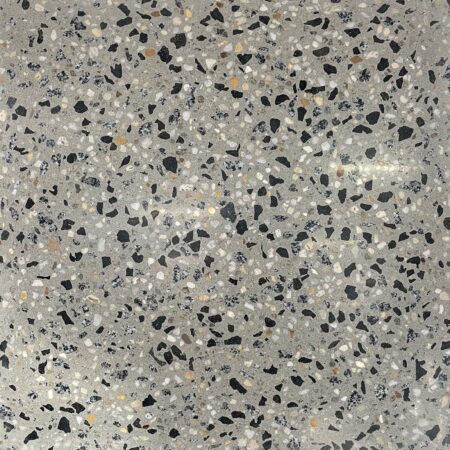

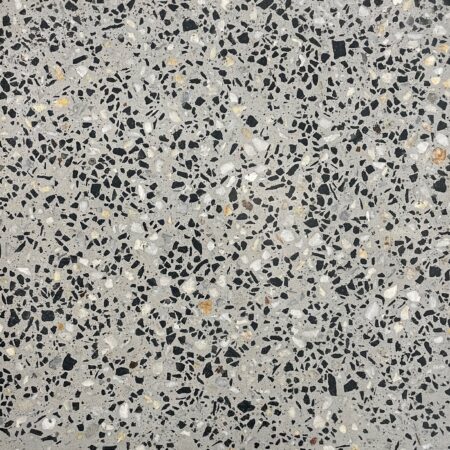

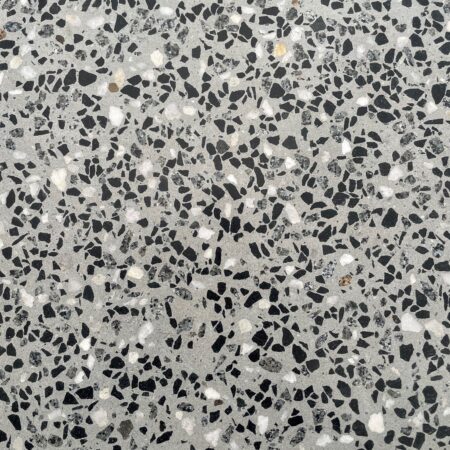

Dull, flat grey concrete is a thing of the past. Today, polished concrete offers stylish solutions favored by architects, designers, and DIY builders. With options ranging from standard grey mixes to custom blends with colour pigments and quality aggregates sourced throughout Victoria, polished concrete enhances any space.

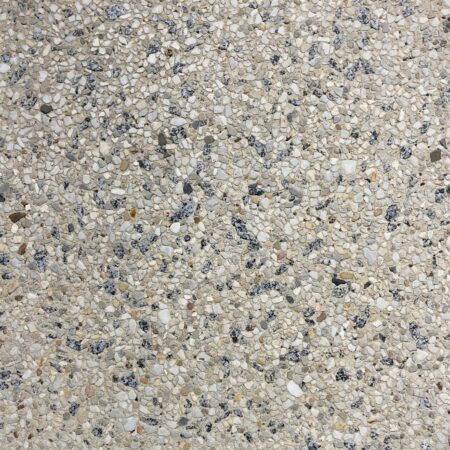

Select your preferred aggregate exposure level, ranging from Nil (minimal visibility) to Random (Salt & Pepper) or Full Exposure (100% aggregate). Complete the look with a choice of matte/satin or a polished 3000-grit finish for a stunning shine.

Visit Our Showrrom

As well as its visual appeal, Polished Concrete is extremely easy to maintain and keep clean. A simple dust and mop with warm water and it’s looking as good as the day it was polished. With our large selection of Polished Concrete mixes and abundant choice of aggregates allows our customers imagination to run riot. While retaining its matchless durability and resistance to wear for which Polished Concrete is so highly prized, it can be easily sculpted to create shapes and structures that would be impossible to achieve with any other material. At Metro Mix Concrete we invite customers, designers and architects to visit our showroom at 42 – 46 Cahill Street, Dandenong South, Victoria, 3175 to view our comprehensive display of polished concrete samples, as well as our newly finished Polished Concrete floors with in slab heating. Our highly-trained sales staff will be more than happy to run you through our range and discuss your ideas with you. With our unrivalled depth of experience in creating custom polished concrete mixes, were sure to come up with a perfect solution for your next project. So, for Polished Concrete Melbourne, contact Metro Mix Concrete today on 1300 Metro Mix or email us here for a prompt response. Speak to us today about having your very own custom designed polished concrete sample created by our creative design team and visit our showroom to see our life-size polished concrete office display, finished in all your different polished finishes.