Today’s most common form of decorative concrete is exposed aggregate. Traditionally, concrete has been finished with a smooth cement surface either trowelled or stippled. The aggregate – the small stones and pebbles, to which concrete owes its great strength, were to be hidden beneath the surface.

Then one day someone realised that the aggregate inside of concrete could be beautiful and more aesthetically pleasing than the cement that bound it together. Not only that, but leaving the aggregate exposed provided a highly fricative and durable surface, making it ideal for pools, driveways, motor traffic and for applications where a nonslip pedestrian surface was required.

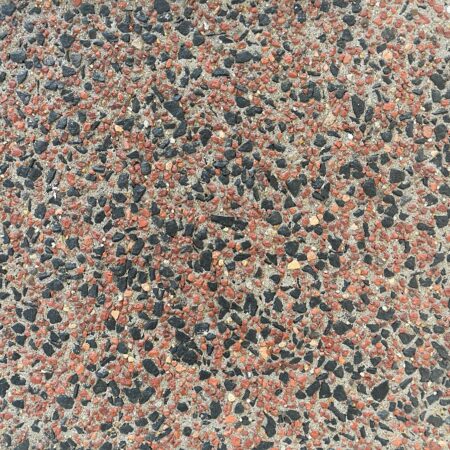

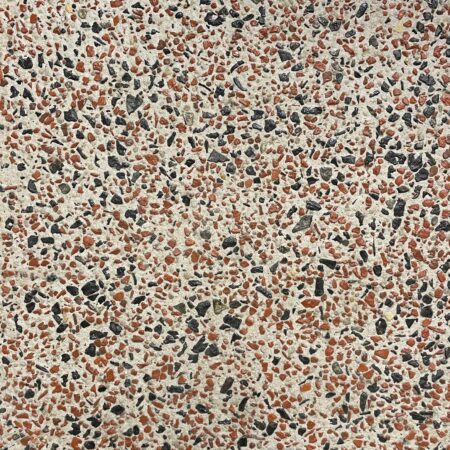

Thus, the exposed aggregate concrete finish was born and no sooner we at Metro Mix Concrete started to work with Melbourne’s architects and designers to diversify and exploit the decorative effects possible with this exciting new finish. From the start, it was clear that the grade of the aggregate could be varied, both to give different frictional properties and to vary the appearance of the surface.

Next, it was realised that different regions produce alluvial gravel and stone of varying textures and colours, suggesting a whole palette of exciting aesthetic effects. At Metro Mix Concrete, our creators invested extensive research into the sourcing of interesting aggregates that combined the structural properties our customers demanded with exciting innovative and beautiful aesthetic effects.

We now offer one of Melbourne’s largest selection of custom concrete finishes which exploit the beauty and functional attributes of exposed aggregate.

With concrete base choices from, grey and charcoal through to off-white and colour oxides, our range of exposed aggregate mixes is set to leave you speechless.

Bring us your design ideas, and our friendly sales team will show you our range we have on display in our Showroom at Clayton South, Melbourne and then sit down with you to work out a unique concrete solution perfect for your project.

So, for the very best in exposed aggregate concrete Melbourne call Metro Mix Concrete today on 1300 Metro Mix.

There’s no mix like METRO MIX.

Please remember that exposed aggregate concrete like normal concrete is made from natural resources and laid by man not machine, there are many elements and variables that can affect the final finish. We suggest using a recommended exposed aggregate contractor.

Exposed aggregate concrete can be used in various ways, such as in; driveways, pool surrounds, internal floors, and outdoor entertainment areas, the possibilities are endless.

Cement is a type of binder, a substance that sets and hardens when added with water, or any other inert durable materials like stone and sand. Its chemical compound allows it to set as hard as rock and can withstand impacts, heat, abrasion, and weathering. Cement is primarily made by heating limestone to very high temperatures to create a material called clinker. The clinker is then ground with a small amount of gypsum into a powder to make ‘Portland Cement’, the most commonly used type of cement. Portland cement is a basic ingredient of concrete, mortar and most non-specialty grout. The most common use for Portland cement is in the production of concrete.

Concrete and cement are usually contrasted together as being similar products. However, cement is actually an ingredient of concrete. Cement is an additive that provides the basis for the glue that holds concrete together. Concrete is a mixture of aggregates (stones) and sand, along with water and cement. The process of mixing these materials is called hydration, where the cement and a portion of water undergo a chemical reaction and harden. This means that concrete “sets” or “hardens” as a result of the chemical reaction – and does not simply dry out. Other special additives can then be added to alter texture, pigmentation, and other properties.

Concrete changes volume when it dries out, this is because of its chemical compound. It cracks due to tensile stress, which is when the concrete expands. The pressure that builds up as a result of this change in volume can cause the concrete to move outward and inwards.

Measures are implemented to reduce the concrete’s ability to crack, such as putting in joints to allow for neat, straight line cracks. These joints also allow the concrete to move when its volume is changed due to expansion and shrinkage. One of the biggest factors that affect concrete is the weather. The risk of cracking is much higher on warm, dry days with low humidity and strong wind.

Call us on (03) 9551 8890

Visit our showroom